Description

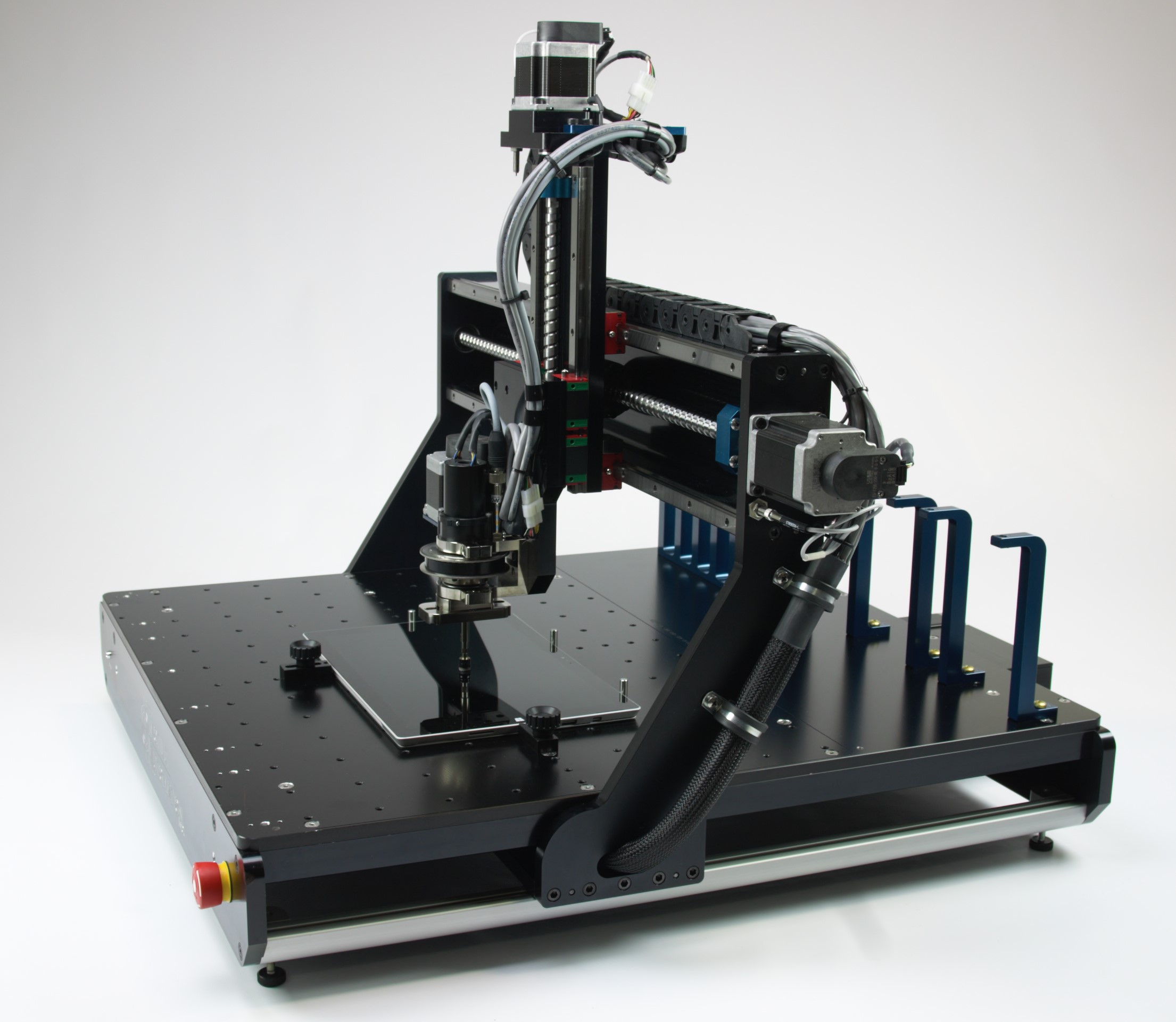

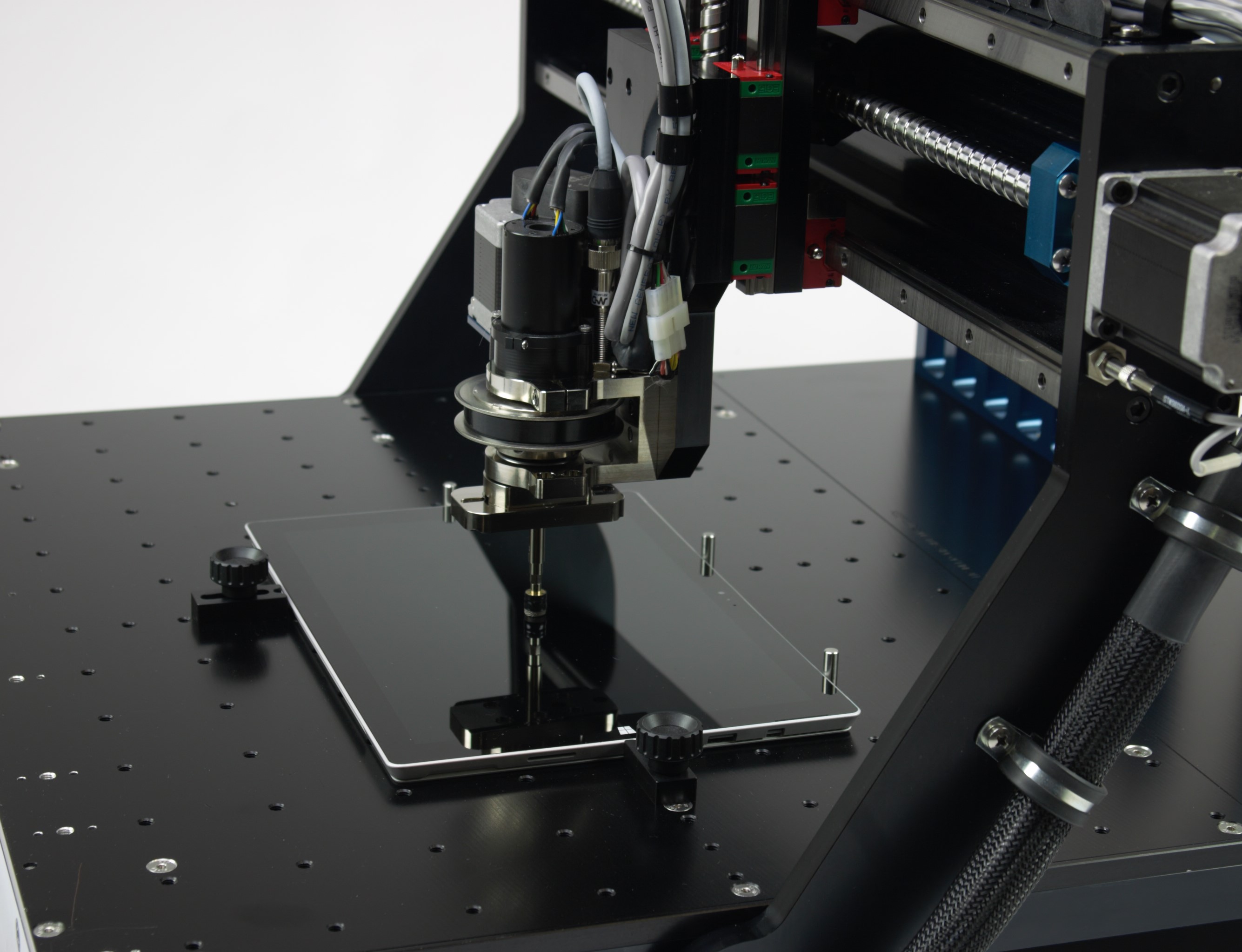

Our Goal was to build one highly customizable testing platform to accomodate various touch test requirements. This allows you to measure a variety of touch sensor characteristics with a single tool reducing capital expenditures and increasing testing capability.

A few advantages

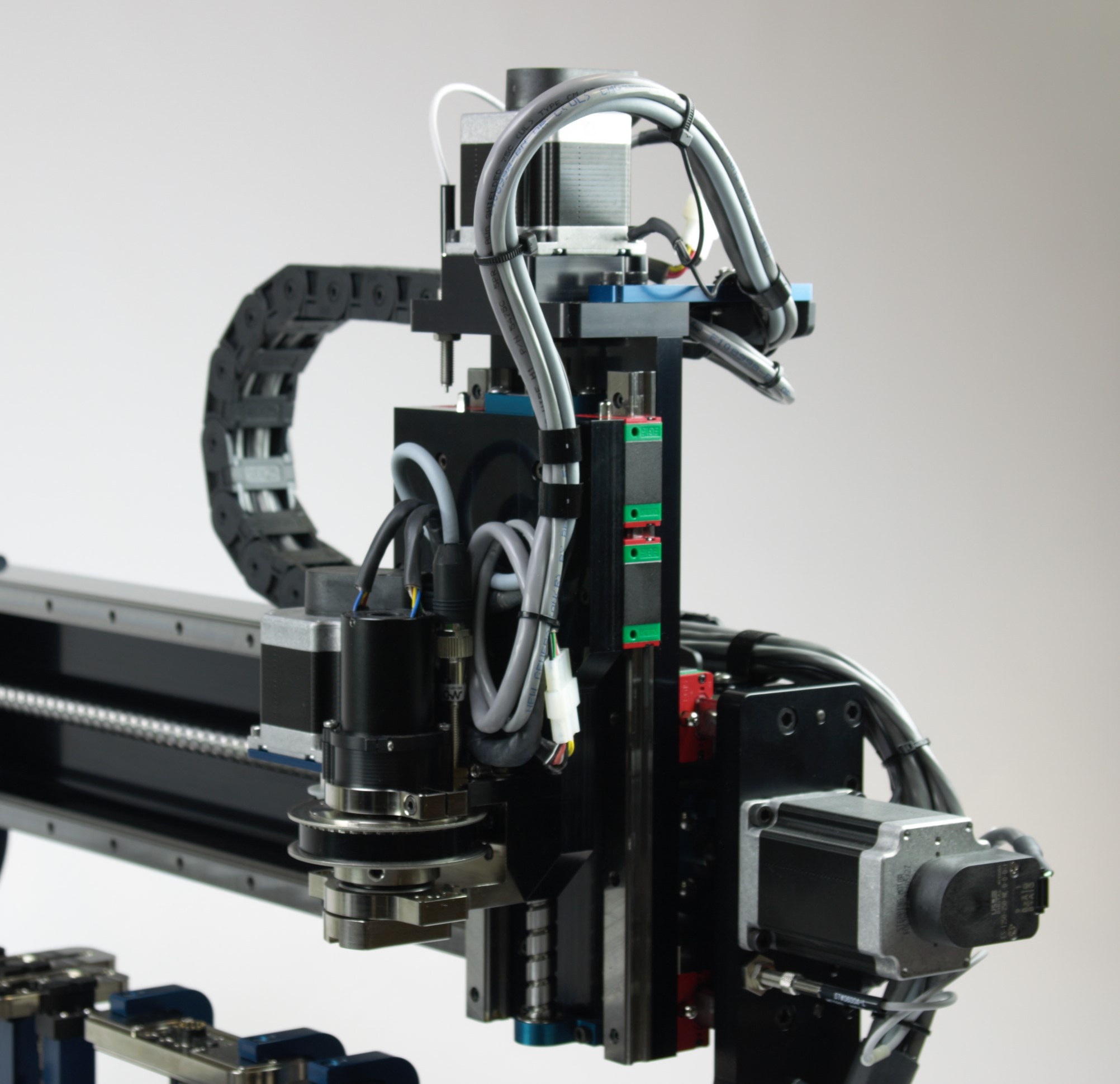

- Supported by a variety of off-the-shelf “touch & pen” specific end effectors.

- Highly mobile benchtop test solution.

- Recommended by the #1 OEM’s in the display industry.

- Designed and manufactured by Tactile Automation in the USA and supported by Tactile globally.

What’s unique? It’s ability to automatically change to a wide variety of touch testing specific end effectors, without pneumatic’s, allows you to efficiently complete multiple tests sequentially without operator input.

Hardware Specs

| Travel Range | S.A.E | Metric |

|---|---|---|

| X Axis | 20.87 in | 530 mm |

| Y Axis | 20.87 in | 530 mm |

| Z Axis | 6.29 in | 160 mm |

| A Axis | 360 deg | 360 deg |

| Clearance between Z Axis and table | 6.41 in | 163 mm |

| Overall Dimensions | S.A.E | Metric |

| Length (Y-Direction) | 32.271 in | 819.7 mm |

| Width (X-Direction) | 30.582 in | 776.78 mm |

| Height (Z-Direction) | 25.097 in | 637.47 mm |

| Weight | 132 lbs | 60 Kg |

| Speed | S.A.E | Metric |

| X Axis | 11.8 in/s | 300 mm/s |

| Y Axis | 11.8 in/s | 300 mm/s |

| Z Axis | 11.8 in/s | 300 mm/s |

| A Axis | 250 rpm | 250 rpm |

| Acceleration | S.A.E | Metric |

| X Axis | 118.1 in/s2 | 3000 mm/s2 |

| Y Axis | 118.1 in/s2 | 3000 mm/s2 |

| Z Axis | 118.1 in/s2 | 3000 mm/s2 |

| Repeatability | S.A.E | Metric |

| X Axis | ≤ ± .0019 in | ≤ ± .05 mm |

| Y Axis | ≤ ± .0019 in | ≤ ± .05 mm |

| Movement Straightness | S.A.E | Metric |

| X Axis | ≤ .0031 in/19.685 in | ≤ .08 mm/500 mm |

| Y Axis | ≤ .0031 in/19.685 in | ≤ .08 mm/500 mm |

| Tool Changer | S.A.E | Metric |

| Type | Magnetic Coupling | Magnetic Coupling |

| Capacity | 13 | 13 |

Software Specs

The TakTouch utilizes the Dynomotion KFlop motion controller which operates on Dynomotion’s KMotion software libraries. More information can be found below or on Dynomotion’s website here.

Dynomotion’s KMotion software libraries contains the following components:

- Dynomotion-developed Trajectory Planner

- Dynomotion-developed Coordinated Motion Library

- G-Code interpreter

- Kinematics Layer with Geo-Correction

- .NET interface

The KMotion libraries are powerful in that they do all of the difficult computational and coordinated tasks for the user. You can create your own software to make use of the libraries directly, or through the .NET framework, or use third-party software that already makes use of the .NET framework such as National Instruments’ LabVIEW.

We also understand your current peripheral systems may operate differently than ours, which is why we provide custom software development and support to ensure our systems interface smoothly with yours. Additionally, we offer “ground up” SW development for your specific needs.

Software Breakdown

| Function | Parameter | Specification |

|---|---|---|

| User Program | Language | C |

| Number Concurrent | 7 | |

| Stand alone mode | Yes | |

| Host Requirement | OS | MS Windows™ XP through 10; 32 and 64 bit |

| Interface | USB 2.0 | |

| Interface Library | Multi-Threaded | Yes |

| Multi-Process | Yes | |

| Multi-Board | Yes | |

| MS Windows™ VC++ | Supported | |

| MS Windows™ VB | Supported | |

| C# | Supported | |

| .NET | Supported | |

| C Compiler | TCC67 | Included |

| G Code | Interpreter | Included |

| Script Language | ASCII Commands | Included |

KFlop Motion Controller Specifications

| Function | Parameter | Specification |

|---|---|---|

| Processor | CPU | TMS320C67-200MHz DSP 1.2GFLOP |

| Memory | 32/64-Bit Native Floating Point; FLASH 2 MBytes; SDRAM 16 Mbytes | |

| Interface | Host | USB 2.0 Full Speed |

| Axis | Type | MicroStep/Servo/Brush/Brushless/StepDirection |

| Environment | Operating Temperature | 0-40° C |

| User I/O | Digital | 8 General Purpose (GPIO) available |

Videos

Automated Microsoft Windows HLK PTP

The TakTouch supports automated Microsoft Windows HLK testing. See approved tools here.

- Reduces the average test time from ~180min to ~45min, a 75% time savings!

- Contact us to learn how you can reduce HLK test time by 75%!

- Click here to view test equipment that is required to complete the Touch-related tests in the Windows Hardware Lab Kit (HLK)

Force Sensing Demo

The force sensing end effector provides the ability to accurately test 3D input

- Accuracy: ± 3g below 100g, otherwise ± 3%

- Force Update Rate: 500Hz

- Max Reporting: 600g (highly configurable)

Uses

Measurable Properties

- Aliasing

- Straight Line Linearity

- Point to Point Repeatability

- Stationary Jitter (single/multiple contacts)

- Tapping Response (multiple contacts, 360°rotation)

- Hand Writing/Drawing with Pen or Touch

- Report Rate

- Force

- Swiping Response (multiple contacts, 360°rotation)

- Reliability

- Converge/Diverge

- Input Resolution

- Key Life Test

- Hover Height Accuracy

The TakTouch is capable of, but not limited to, assisting in the measurement of the above listed properties of touch and pen input devices from component to device level.

Gesture Capability

- Single/Multi Finger Tap

- Single/Multi Finger Swipe

- Pinch to Zoom

- Force Sensing

- Palm Rejection

- Stylus/Pen

Test Capability

- Development

- Design Verification

- Reliability/Stress

- Repeatability

- SW & HW Regression

- Manufacturing

Sensor Types

- Capacitive

- Projected Capacitive

- Resistive

- SAW (Surface Acoustic Wave)

- Infrared

- Optical

Reviews

There are no reviews yet.